Our highly motivated team and our modern 5-axis milling centres from HERMLE and DMG enable us to machine small or large production series with maximum precision and in a highly dynamic way. With our 5-axis machine concepts, we can ensure time-parallel equipping and efficient production with minimal personnel input, which leads to maximum productivity and economic efficiency.

The use of simultaneous 5-axis machining technology enables a significant increase in efficiency and productivity in precision milling. In conjunction with our powerful measurement technology, we are the ideal partner for producing high-precision milled parts, even in extremely demanding boundary areas.

Whether it’s delicate parts in instrument construction, sophisticated die-cast housings or block material, our parts have a tolerance range of less than 0.02mm and for this reason they demand the highest process reliability.

High process stability

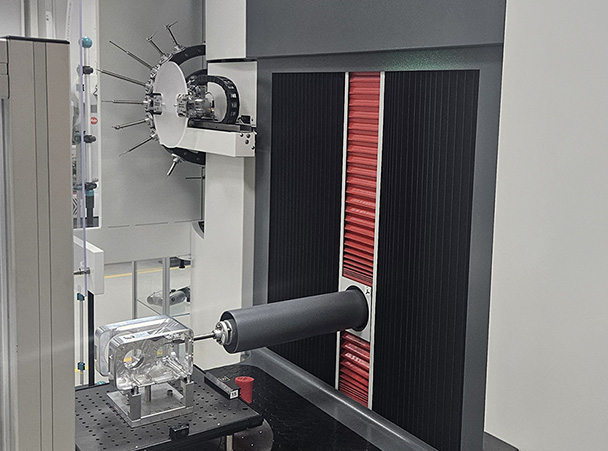

Optimised process control in the production environment is possible with our Leitz SIRIO XI measurement robot. Production employees can measure their workpieces independently around the clock and make the corresponding corrections to the machining parameters if necessary.